Birth Boot Camp: The One & Only Complete Natural Childbirth Course Featured Online

Birth Boot Camp is proud to be the only truly independent, full-length “real” childbirth class offered online.

I am a huge advocate of taking a natural, independent childbirth course during pregnancy.

Unfortunately, there aren’t as many classes as there are couples who would benefit from the information they provide. In some small towns across America, the only programs available are run through local hospitals, are usually free and run for just one day.

This just won’t do! So imagine my excitement when I learned of Birth Boot Camp, which features a complete 10 week natural childbirth program online. Birth Boot Camp also certifies instructors, which are slowly springing up around the country.

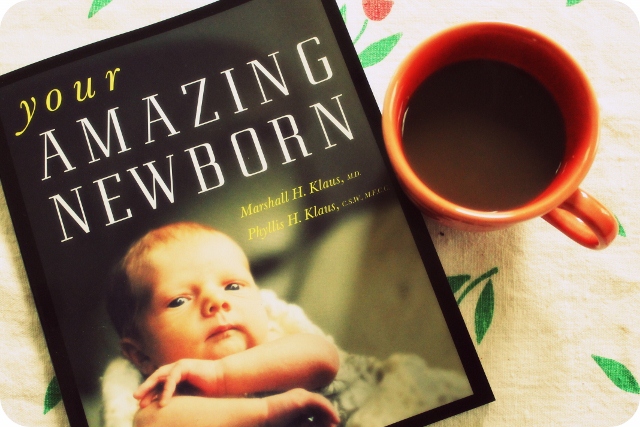

Online classes run 1-2 hours and are taught by childbirth educator and founder of Birth Boot Camp, Donna Ryan. Each class is professionally recorded and edited with clips from other birth professionals, alongside birth stories from dozens of couples. When you enroll in the online classes, you will receive a beautiful, full-color workbook called the Field Guide. It’s packed with additional information to accompany each class including several relaxation exercises, weekly Chow Charts, labor charts, an individualized kegel program, a very effective sample birth plan, and the list goes on!

Also included is a 2 disk Breastfeeding DVD – The Ultimate MRE (Meal Ready to Eat) – taught by Lactation Consultant Mellanie Sheppard, IBCLC, RLC.

“We LOVED the classes. They were perfect. When I was pregnant, we have a nice big jacuzzi bath tub we use to bath in together, and we would sometimes watch the videos during bath time. There was more than just one occasion where someone’s either story, or video would make us sob into each others arms from the shear beauty of everything. The videos gave us reassurance that we were not on some pilgrimage to pull off something no one had ever done before. It was great to hear that others had not only done it, but instinctually did it well. I’m very grateful our midwife recommended Birth Boot Camp for us to take.” ~Ashton

There are many reasons why couples choose online classes.

Online classes can be watched on your time schedule. Imagine that you just found Birth Boot Camp at 35 weeks! No problem. Maybe you live where no independent natural childbirth classes are taught. No problem.

A great way to use this course is to put the classes on your calendar and then “attend” class each week, just like you would if you were in a live class. Then, do the assignments, practice the relaxation and exercises, and eat well. It’s the “homework” that makes Birth Boot Camp such a great experience for couples. We bet you’ll even be a stronger couple as a result, ready to welcome your new recruit into your family.

“Classes have been awesome. I don’t want this to sound creepy, but I wish I could come out to Texas and give you a hug! I just love listening to you…and you even have my husband intrigued, asking when our next popcorn/movie night will be! ![]()

I’m due on June 15th… getting closer…. trying to be patient and relax as much as possible. I feel so prepared — I’m actually excited. I can hardly wait! Thanks for a great resource!” ~ Kiera

Natural childbirth preparation is important for every birth – be it your first or third. Visit Birth Boot Camp’s official website, BirthBootCamp.com, to learn more about taking an online class, find out whether an instructor lives near you, or discover how you can become a Birth Boot Camp Instructor.

1 comment

Post a comment

none other. A trainee needs to allow approximately 6-9 months to complete the requirements before coming to their chosen workshop.

none other. A trainee needs to allow approximately 6-9 months to complete the requirements before coming to their chosen workshop.

I took these classes, and they were great! Highly recommended. The workbook is a great resource too